Decades of Diagnostic Device Valve Experience

Humphrey Products has developed innovative valves for diagnostic applications solutions for over 30 years. It all began in 1990 when our inert isolation valves were among the first selected to manage aggressive and corrosive liquids present in biomedical instruments.

Today, our plastic inert diaphragm valves are used in clinical chemistry, diagnostic equipment and kidney dialysis applications to handle aggressive media, such as blood products, bodily fluids, reagents, diluents and disinfecting agents. And our engineers continue to pursue innovative design solutions to fit niche medical diagnostic device applications and industry demands.

Trusted by Diagnostic Professionals Worldwide

Our engineers keep a close eye on the changing needs of diagnostic solutions providers. Based on the information we acquire, we design innovative products that can handle the increasing demands of modern workflows.

How Our Valves Are Used in Biomedical Instrumentation

Clinical Chemistry

If not handled properly, volatile chemicals in the clinical chemistry profession can pose safety risks and cause damage to equipment. Using the right valves can ensure that these media are responsibly managed when moved between endpoints.

Diagnostic Equipment

Diagnostic equipment can involve both the use of chemicals and human bodily fluids to provide an accurate diagnosis. If handled improperly, these media can spoil and impede a medical professional’s ability to provide a more accurate diagnosis for the patient.

Kidney Dialysis

During dialysis, unfiltered blood is continuously replaced with clean, filtered blood. The movement of the blood and dialyze fluid through the dialyzer system needs to be managed impeccably to ensure the patient receives an infusion of the cleanest blood possible.

Custom-Engineered Solutions for Diagnostic Devices

Manufacturers of medical diagnostic equipment need a solution that works with their design – not something they have to attempt to build their design around. Our engineers work closely with leading manufacturing entities across all medical niches to develop specific valve solutions for their fluid control systems.

Through trusted collaboration, a combination of core skills, and aligned purpose, we can integrate our products and other elements to meet design requirements, easily integrate into production processes, and offer low costs to our customers.

Key Benefits of Working with Humphrey Products

Select from a variety of proven and unique valve designs and proprietary sealing technologies. Leverage our team’s 25+ years of experience collaborating with client engineers as a fluid system control partner. Take advantage of our regulatory experience and process control systems for medical devices.

Our Process

Challenge

We begin working closely on a peer-to-peer basis with your engineers early in the design process to understand your specific needs.

Concept

We often present multiple concepts and will recommend a design that provides maximum benefits for what you need.

Solution

We finalize the design using proven Humphrey valve technology and assist you in moving quickly from prototype to production.

Result

We implement your solution, measuring actual results to the original technical, commercial, and schedule expectations. We continually explore ways to reduce costs.

Proven Diagnostic Device Solutions

Our diverse portfolio offers a broad range of solutions for medical diagnostic applications. Each one is designed to provide superior automation and material handling for a variety of fluids, including cleaning materials, reagents, and bodily samples with precision staining capabilities for a more accurate diagnosis.

Let our Life Science Group provide the valves in your next innovation.

Popular Valve Solutions for Diagnostic Devices

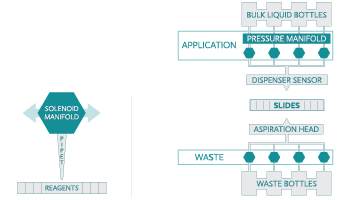

Application Waste/System Solutions

Application & Disposal

- Completely isolated flow path from solenoid actuator.

- Materials of construction suitable with most solutions.

- Liquid proof coil prevents fluid entrapment that causes failure.

Solenoid Manifold

Material Handling/Automation Solutions

- Very compact, lowest cost manifold solution we offer.

- Very low leak rates possible.

- Low power consumption, oxygen compatible.

Get the Right Solution for Your Diagnostic Device

We help bring your vision for medical diagnostic applications to life by providing consistently reliable custom valves for your system requirements. To experience the Humphrey difference, contact us anytime to learn more or have your questions answered.