Improving Access to At-Home Dialysis Treatment

Humphrey Products has expanded its diaphragm isolated iDP Series 2- and 3 port solenoid valves used successfully in kidney dialysis equipment over the past 30 years. Added to the line-up is the unique MiDP (motorized inert diaphragm poppet), a proportional valve that provides consistent variable flow performance and with improved features to maximize function.

We’re committed to producing top-rated medical device valves that deliver on our promise of providing our customers with the latest solenoid valve technology. Our valves are compact and durable, making them appropriate for repetitive functions and dialysis treatment applications.

iDP Kidney Dialysis Valve Features

The diaphragm isolated solenoid valve has recently added FFKM elastomers to the Radel and EPDM or VitonGF wetted materials, improving its range of chemical compatibility. In addition, it can withstand fluid temperatures up to 203° Fahrenheit, and the encapsulated coil allows for reliability in wet environments.

The iDP valve can meet the demands of diverse dialysis applications. It’s built and tested to achieve a minimum of 5.3 SLPM at 40 psid for liquids.

Additional features include:

- Loctite impregnated coils that tolerate saline submersion

- 2- and 3-way valve types

- Manifold mount option

- Servo valve driver for unmatched proportional control (MiDP)

- New FFKM premium elastomer for extreme chemicals and temperatures

The unique design of our hemodialysis valves provides better response times, lower temperature ratings, improved temperature ranges, and market-leading reliability and elastomer options.

Why Work with Humphrey Products

Humphrey Products is committed to excellence and providing the customer with a unique client experience. Humphrey engineers are industry experts trusted worldwide, and when standard valves fall short, they are well-versed in custom biomedical valve solutions. Humphrey recognizes their products can positively impact the well-being of others, and this role is not taken lightly. With equipment specifications guiding the partnership, Humphrey strives to deliver a product that exceeds your expectations.

Our Process

Challenge

We start by working at a peer-to-peer level with your engineering team from the earliest stages of the design process to understand your specific project requirements.

Concept

We develop multiple concepts based on your needs and will recommend a design that provides the most optimal benefits for your application.

Solution

We develop and present a finalized design using proven Humphrey valve technology. After your approval, we transition seamlessly from prototyping to production.

Result

Once your solution is implemented, we remain a close partner for any future needs and developments. We will continue to explore new options to reduce costs for you.

Popular Dialysis Equipment Valves

Application Waste/System Solutions

- A completely isolated flow path

- Suitable materials for most devices

- Encapsulated coil operation in wet environments

Motorized inert proportional valves

- Compact design

- Very low leak rates

- Low power consumption

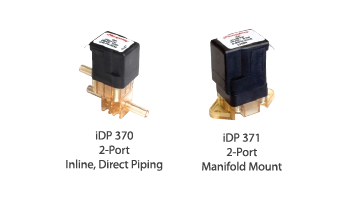

iDP 350/351 and 370/371

These inert solenoid valves are engineered to control aggressive liquids and gases in the harshest environments. The flexing diaphragm poppet design isolates the solenoid from media penetration, while the inert body material ensures long life and sustained performance.

Ready to Get Started?

Contact us and a representative will work with you to determine which valve solutions best suit your application. We look forward to building new partnerships and addressing needs to improve the lives of others.

Real-Life Applications for Dialysis Valves

Want to see our products in action? View and download our case study.